Portable Evaporative Cooler

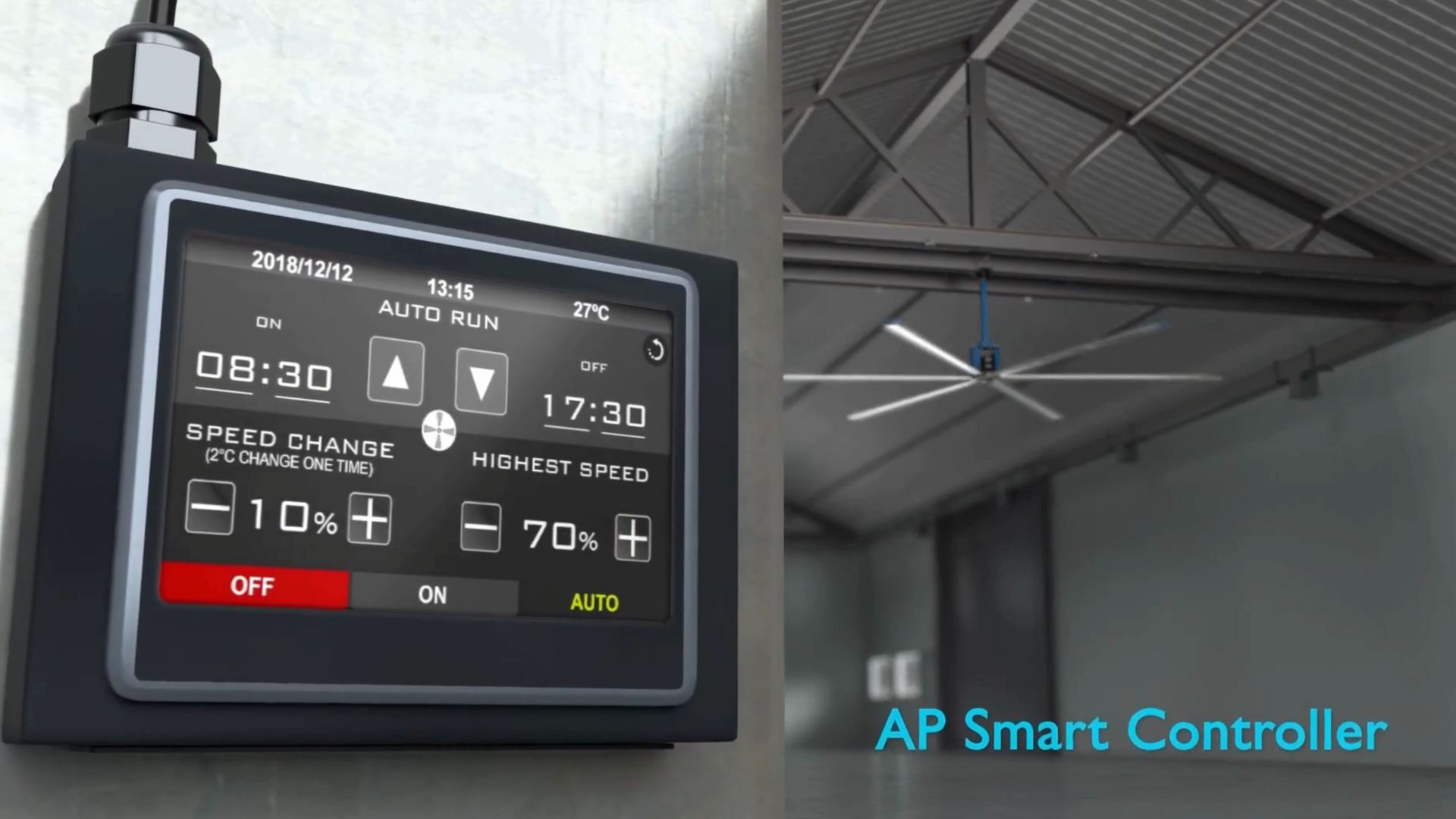

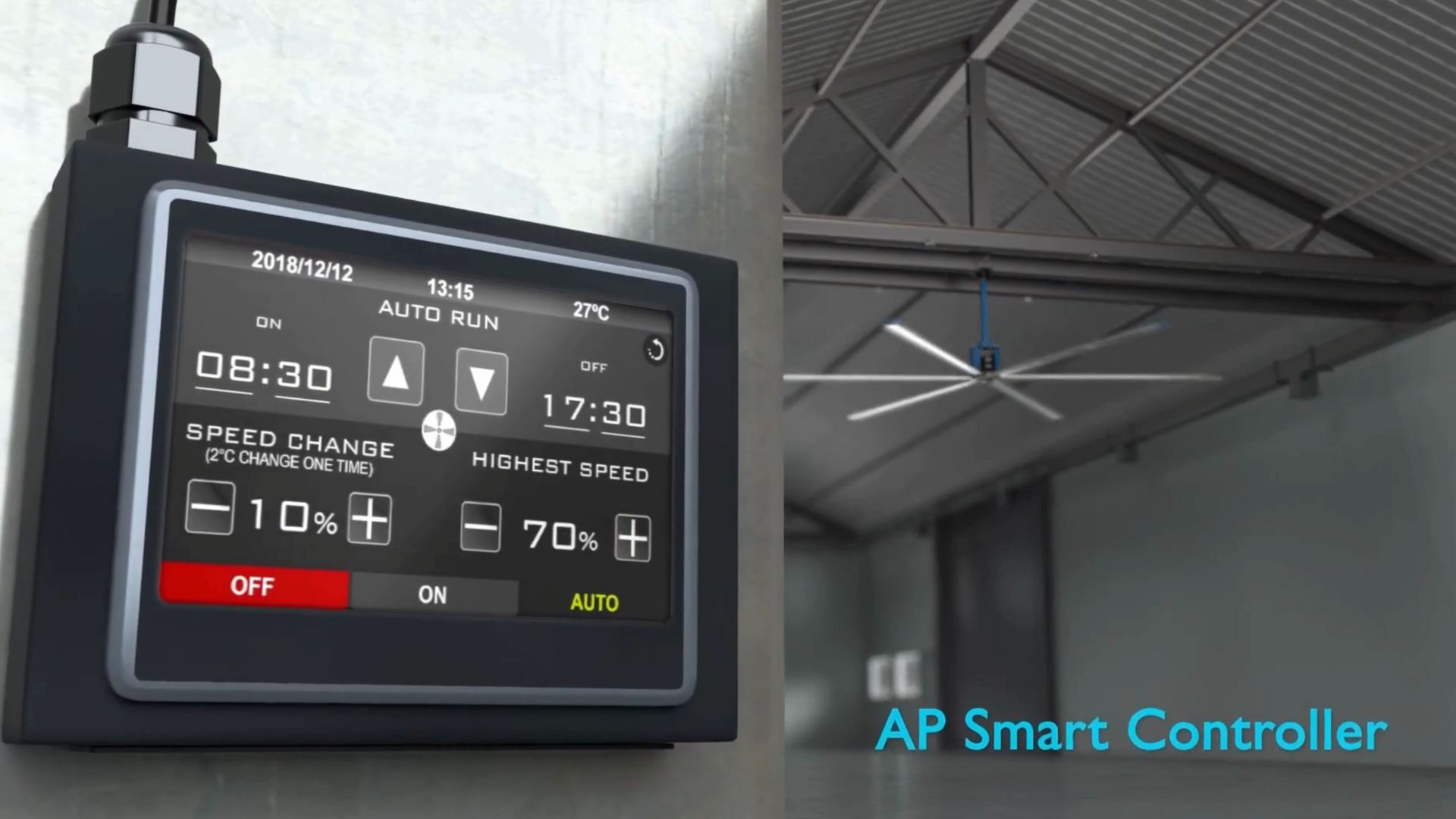

Portable HVLS Fans

Portable HVLS Fans

To ensure the fan installation meets the required standards, the site survey is the most important step in providing an accurate quotation. The company's project engineer will conduct a site survey to gather information such as the installation area, standard dimensions for positioning, and may propose a wind flow simulation plan to optimize ventilation efficiency.

Whether you have a large warehouse or a small store, our experts are always ready to create a customized solution that makes your life easier, more comfortable, and more cost-effective.

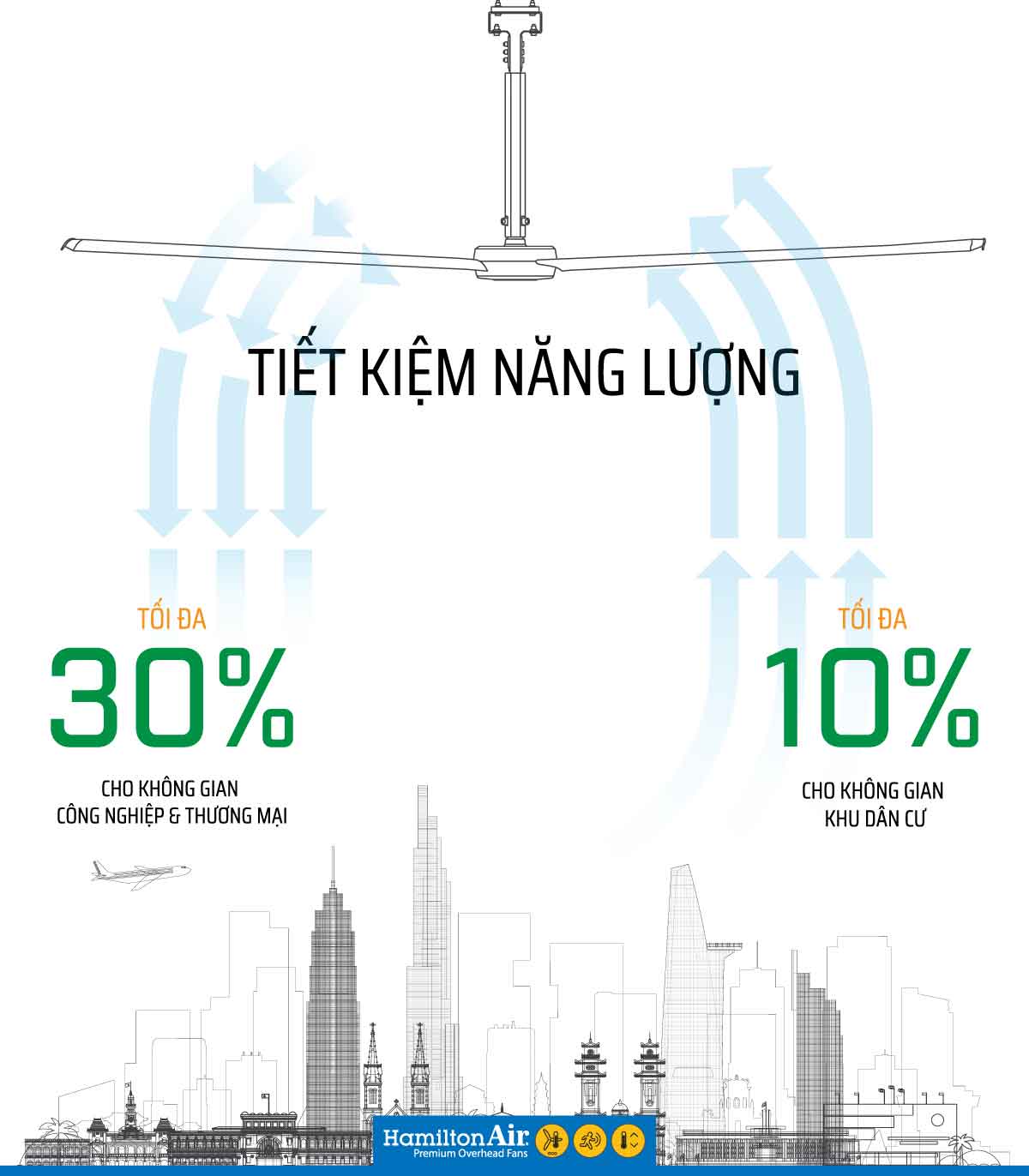

During the scorching summer months, cooling the living space becomes essential. Whether you're at home or in the office, having a cool and comfortable environment helps improve work efficiency, health, and overall well-being. However, air conditioning can be costly, while fans provide a more affordable and effective solution for cooling.

Whether you have a large warehouse or a small store, our experts are always ready to create a customized solution that makes your life easier, more comfortable, and more cost-effective.

To ensure the fan installation meets the required standards, the site survey is the most important step in providing an accurate quotation. The company's project engineer will conduct a site survey to gather information such as the installation area, standard dimensions for positioning, and may propose a wind flow simulation plan to optimize ventilation efficiency.

Whether you have a large warehouse or a small store, our experts are always ready to create a customized solution that makes your life easier, more comfortable, and more cost-effective.

During the scorching summer months, cooling the living space becomes essential. Whether you're at home or in the office, having a cool and comfortable environment helps improve work efficiency, health, and overall well-being. However, air conditioning can be costly, while fans provide a more affordable and effective solution for cooling.

Whether you have a large warehouse or a small store, our experts are always ready to create a customized solution that makes your life easier, more comfortable, and more cost-effective.

- Installation Guidlines SUNON

- Installation Guidlines Hamilton Air

- List ItemInstallation Guidlines Big Ass Fans